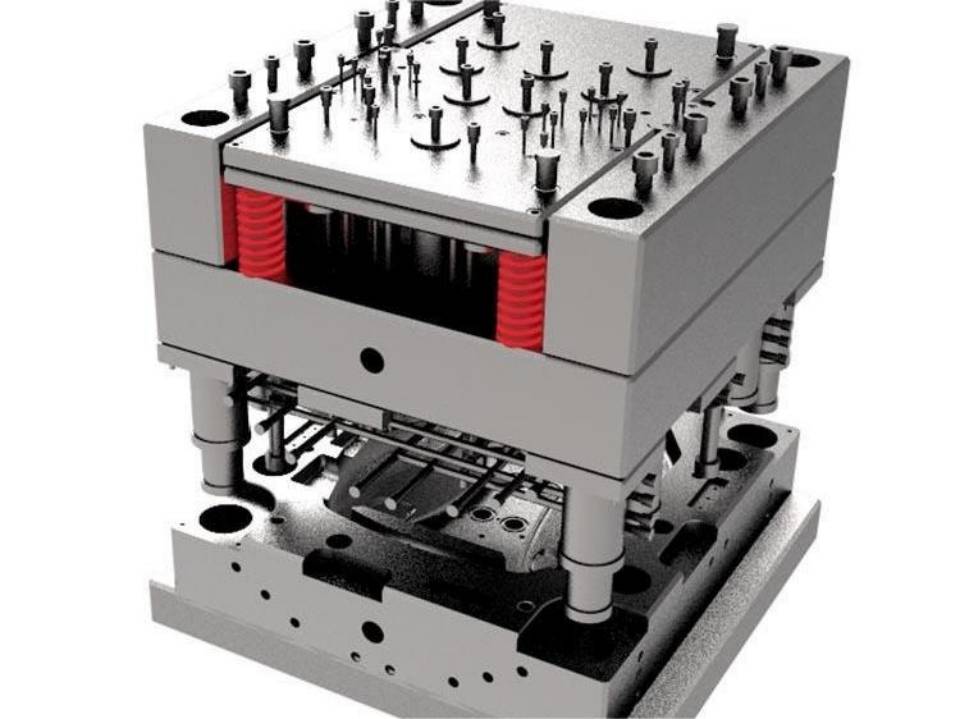

The key to lunch box production - injection moulds

2022-10-16 22:00

The injection mold of lunch box is composed of many steel plates and various parts together, which generally includes molding device, positioning device, cooling system, constant temperature system, flow channel system, etc.

The injection mold can be recycled during the whole process. The mold is mounted on an injection molding machine and the plastic is injected into the mold for cooling and shaping into the shape of a lunch box. The upper and lower parts of the mold are separated and the prefabricated parts are removed. Therefore, the use of injection molds can greatly improve efficiency and save costs.

Both the precision of plastic products and the efficiency and cycle time of the injection molding process are closely related to the injection molds, which can be said to have a direct impact on the quality of the products. BOX Household's lunch boxes are injection molded, and the molds for each accessory possess an unparalleled high degree of precision.

We have the best mold precision and quality in the industry. We have the ability to develop our own molds, so we have very strict control over our molds to ensure that each customer's mold will last a long time without much loss of precision. And we pay great attention to the maintenance of the molds in order to prolong the service life of the lunch box molds. From the data, the average service life of each of our molds is 200,000-300,000 times, which is far beyond the level of our peers.